Thermally conductive potting compounds allow greater power-density electronics (Whitepaper)

[ad_1]

Sponsored by Parker Lord.

Now greater than ever, we’re seeing a robust development towards the electrification of automobiles within the transportation business, together with vehicles, buses, trains, off-road automobiles, watercraft and plane. In these electrical automobiles, lengthy ranges and excessive horsepower require excessive energy density from their electrical parts akin to batteries, motors and mills, and the ability electronics wanted for operation. The development is concentrated on smaller, cheaper parts that may save house and cut back prices whereas boosting energy effectivity.

A key problem in creating these parts is to handle the warmth generated by smaller, high-power gadgets like on-board battery chargers, energy inverters and converters and electrical machines. Thermally conductive potting compounds are perfect for quickly and successfully conducting warmth away from energy parts to the warmth sink. The potting compound fills the element enclosure, leaving no air gaps. In consequence, warmth is dissipated throughout the enclosure and quickly carried out to the warmth sink, which has enabled substantial dimension and weight reductions of the completed element.

In Parker Lord’s whitepaper “Thermally Conductive Potting Compounds Allow Greater Energy Density Electronics,” they share the outcomes of a examine carried out by a workforce of Parker Lord and Manzanita Micro consultants who examined the warmth rise of inductors potted in a liquid-cooled aluminum fixture.

Supplies used within the examine

On this examine, they used 5 silicone potting supplies. All of the supplies are electrically insulative with excessive dielectric power and high-temperature stability. These silicone potting supplies embrace:

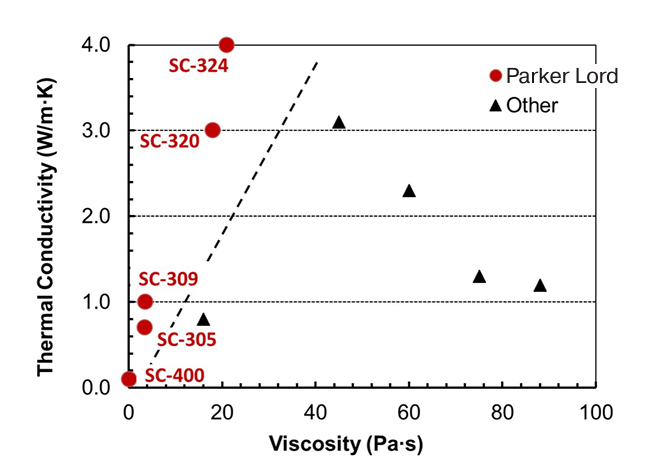

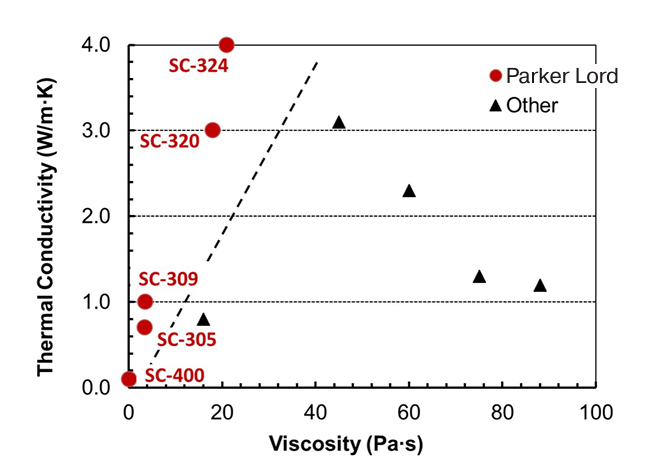

- Thermoset® SC-400 Silicone Encapsulant: a transparent, gentle gel with low thermal conductivity (0.1 W/m∙Okay) used for potting delicate electronics the place excessive dielectric power and really low mechanical stress are desired.

- CoolTherm® SC-305, SC-309, SC-320 and SC-324 Thermally Conductive Silicone Encapsulants: Crammed silicone potting supplies with progressively greater thermal conductivities of 0.7, 1.0, 3.0, and 4.0 W/m∙Okay, respectively.

These supplies are at present being utilized in quite a few functions to guard delicate digital parts from extra warmth, together with on-board chargers, inverters and electrical motor stators for EVs.

A key differentiating property of their thermally conductive silicone supplies is their low viscosity in comparison with aggressive supplies with related thermal conductivity. The decrease viscosity permits Parker Lord’s supplies to circulation and fill voids extra readily whereas offering wonderful thermal conductivity. They’re additionally simpler to degas, which means that elements might be potted which are basically void-free if a vacuum potting course of is used.

Inductor potting and testing

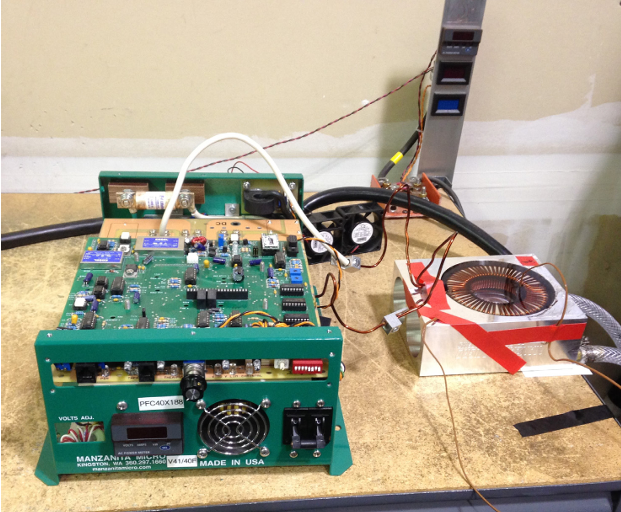

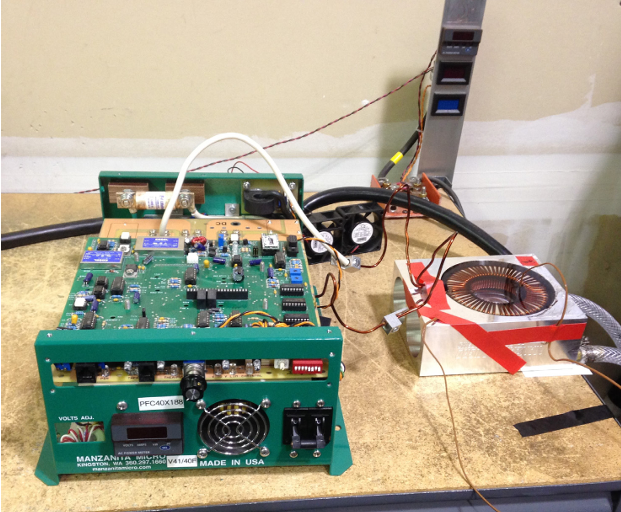

The inductors used on this examine had been constructed from Micrometals T400-61D high-temperature, magnetic-powder toroid cores wrapped with 62 turns of 10-gauge insulated copper wire, which yield about 500 μH inductance at load. Inductors had been potted in custom-made aluminum cooling plates fitted with liquid inlet and outlet ports for connection to an exterior circulating fluid tub. The 5 totally different supplies had been used to pot three inductors with every materials, leading to a complete of 15 potted inductors.

Earlier than potting, every inductor was fitted with a thermocouple to measure its temperature. The situation of the thermocouple corresponds to the most well liked location within the inductor as judged qualitatively from a thermal digicam picture of an unpotted inductor below load.

For the thermal checks, every inductor was related to a Manzanita Micro PFC40X-188 charger passing 9.3 kW and 40 A at 240V enter with 0.98 energy issue. The facility on the inductor was 30W. The aluminum cooling plate was related to a temperature-controlled liquid tub; every inductor was examined at coolant temperature set factors of 25°C, and the everyday automotive coolant temperature of fifty°C. A second thermocouple was connected to the outside of the cooling plate to observe temperature modifications throughout the take a look at; nonetheless, the temperature rise of the cooling plate was lower than 2°C, even in probably the most excessive instances.

Throughout every thermal take a look at, the temperatures of the inductor and cooling plate had been recorded utilizing an Omega Comfortable knowledge logger. The cooling plate and inductor temperatures had been allowed to stabilize with no energy. Energy was then utilized, and the temperature was monitored till the inductor temperature stabilized. The equilibration time was chosen on the level when the temperature reached a gradual state (i.e., no additional temperature improve passed off), and the reported temperature rise was calculated as the ultimate temperature of the inductor minus the preliminary temperature.

Outcomes

In the course of the examine, they used 5 of their silicone potting supplies and examined 15 inductors a minimum of as soon as with a number of examined a number of occasions to find out repeatability. Error bars are plus and minus one normal deviation of the info, which incorporates part-to-part variation and repeatability.

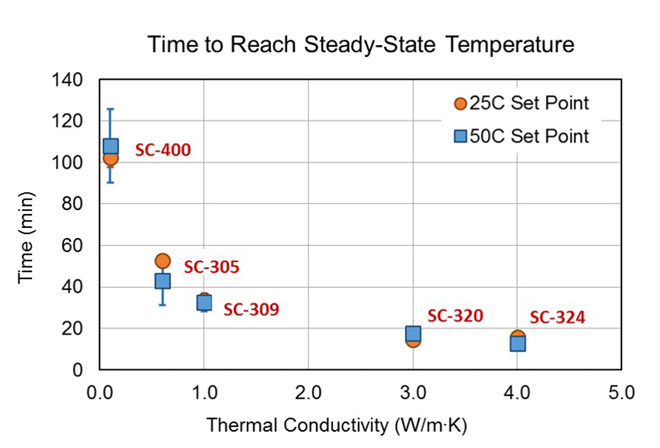

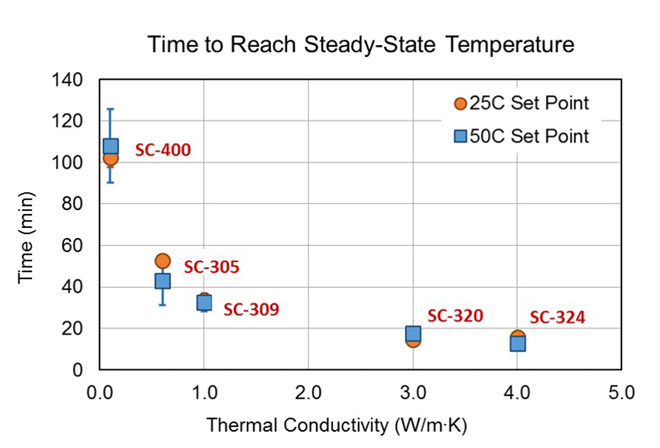

The info present that each the inductor temperature rise, and the equilibration time are impartial of the coolant temperature, as the info at 25°C and 50°C are practically superimposable and throughout the take a look at variation. It is very important be aware that the variation turns into a lot smaller because the thermal conductivity will increase because of the simpler thermal connection to the aluminum cooling plate.

Evaluating an inductor potted with an insulating materials (0.1 W/m∙Okay) to probably the most conductive materials (4.0 W/m∙Okay), the warmth rise is decreased by about 50°C, and the time required to succeed in a secure temperature is decreased from practically two hours to fifteen minutes. These important enhancements in warmth administration allow the event of considerably smaller energy electronics.

Dramatic reductions in each temperature rise and equilibration time are noticed for inductors potted with thermally conductive supplies. The common temperature rise with Parker Lord’s Thermoset SC-400 encapsulant was about 55°C, and the typical rise for the corporate’s most thermally conductive supplies, CoolTherm SC-320 and SC-324 encapsulants, was lower than 10°C. Even the reasonably conductive silicones, CoolTherm SC-305 and SC-309 encapsulants at 0.7 and 1.0 W/m∙Okay, respectively, supplied important enhancements.

Below totally different take a look at circumstances that may generate a temperature rise a lot better than 55°C, the advance would probably be much more pronounced. Equally, the equilibration time was additionally dramatically diminished with the upper thermally conductive supplies. With the non-conductive silicone, Thermoset SC-400 encapsulant, practically two hours was required to succeed in a gradual state, whereas a secure temperature was achieved in lower than 20 minutes for CoolTherm SC-320 and SC-324 encapsulants.

This fast temperature restoration implies that warmth is dissipated shortly, and parts will spend much less time at elevated temperatures, thus rising the lifetime of the parts.

Conclusions

Correct thermal administration is important for creating energy electronics which are smaller and lighter. And smaller and lighter means greater energy density. Because the examine proves, utilizing thermal administration supplies gives the distinctive mixture of excessive thermal conductivity and low viscosity in addition to substantial reductions in each most temperature rise and the time to succeed in a secure temperature. Each advantages result in enhancements in effectivity and element lifetime, thereby enabling high-performance energy electronics.

Parker Lord’s workforce, comprised of seasoned technical assist and utility engineers, is ready to help you all through your energy digital design course of. Their huge expertise contains working with electrical automobile OEMs and battery firms on cutting-edge expertise. Nonetheless, their scope extends past batteries. They’re dedicated to making sure that energy electronics – together with inverters, converters, and e-motors – operate safely, reliably and effectively by implementing efficient thermal administration methods.

When you’d prefer to be taught extra about options for energy electronics, please attain out to their workforce.

To learn the whitepaper, “Thermally Conductive Potting Compounds Allow Greater Energy Density Electronics,” go to their web page to obtain it now.

[ad_2]

Supply hyperlink

Leave a Reply