Henkel’s high-performance battery sealing know-how

[ad_1]

Sponsored by Henkel.

Delivering Innovtion, Experience and Reliability For Battery Producers Globally

After a long time constructing a repute for efficiency and reliability amongst international OEMs and part suppliers, Henkel has expanded its broad portfolio of adhesives, sealants, and purposeful coatings to serve EV producers with revolutionary options throughout the EV phase. On the subject of guaranteeing the security and sturdiness of EV batteries, correct sealing is without doubt one of the most crucial efficiency components. Henkel is a worldwide chief within the battery sealing class, delivering high-quality merchandise, providing in depth manufacturing experience, and collaborating with prospects and companions to unravel the trade‘s most urgent challenges. OEMs and battery producers admire the services Henkel provides as they push their EVs to attain ever-increasing requirements for vary, reliability, price effectivity, security, and circularity. Efficient battery sealing is the muse for best-in-class battery efficiency. With out a dependable seal, all the know-how and vary developments a producer can marshal will in the end fail. Henkel has the sensible know-how and the succesful portfolio to assist make the following technology of EV batteries succeed.

Battery Sealing Issues

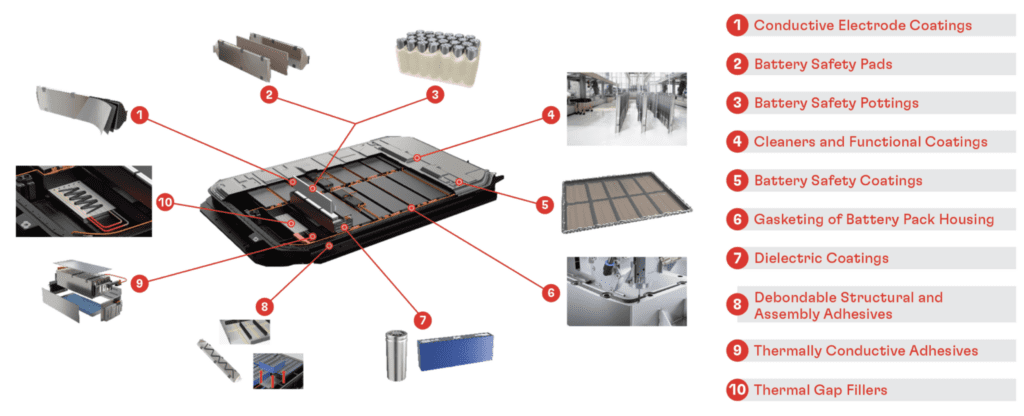

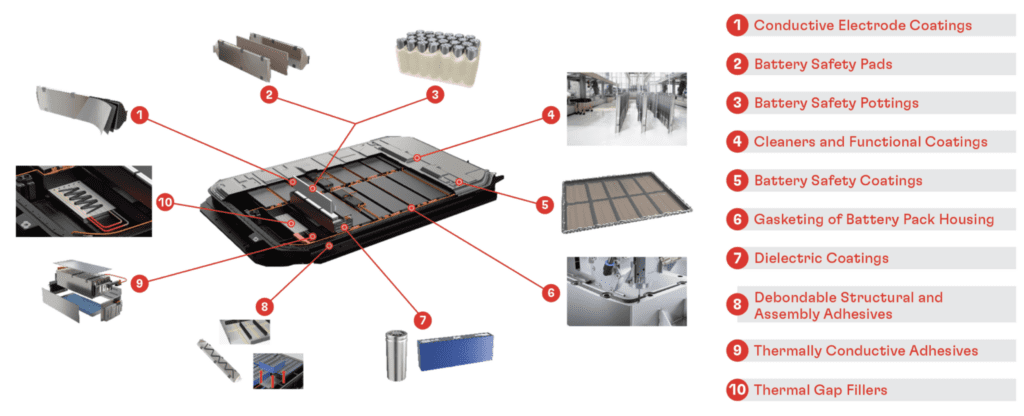

Henkel provides a variety of options for EV battery techniques

Battery pack perimeter sealing functions are only one ingredient in a wider group of superior supplies, resembling adhesives, thermal interface supplies, and battery security supplies that work in live performance to protect and shield your entire symphony of important EV parts. Whereas thermal and electrically conductive supplies typically get the limelight, battery pack seals do the heavy work of defending the battery parts from intrusion by moisture, mud, and different particles. With out satisfactory sealing, EV batteries are vulnerable to untimely failure, brief circuiting, and even thermal runaway, all of which introduce security considerations for patrons and producers alike. Battery sealing and battery security go hand in hand.

Sealer Reliability Issues

Henkel’s high-performance sealers guard the battery pack inside by working at the side of – or rather than – standard fasteners to create a steady, sturdy barrier in opposition to contamination. When precisely spec’d and correctly utilized, Henkel’s sealer portfolio is second to none in the case of sturdiness, reliability, and battery part safety. Henkel places every of its sealing options by means of rigorous long-term and short-term assessments for power, environmental resistance, corrosion efficiency, and rather more. EV part producers that use Henkel merchandise persistently understand distinctive ends in each testing and sensible buyer expertise. Dependable EV producers ship dependable batteries, and probably the most dependable batteries use dependable sealers from Henkel.

Sealer selection Issues

On the subject of battery sealers, one dimension doesn’t match all. Henkel companions with OEMs and battery producers early on within the design part to pick out probably the most appropriate formulation for the job. With a broad international portfolio of sealers available, Henkel’s engineering crew can typically discover an off-the-shelf answer to unravel design challenges shortly. Whether or not the scenario calls for silicone, non-silicone, foam, stable, everlasting, semipermanent, or even absolutely detachable options, Henkel has the product portfolio to stop potential issues or appropriate current manufacturing considerations.

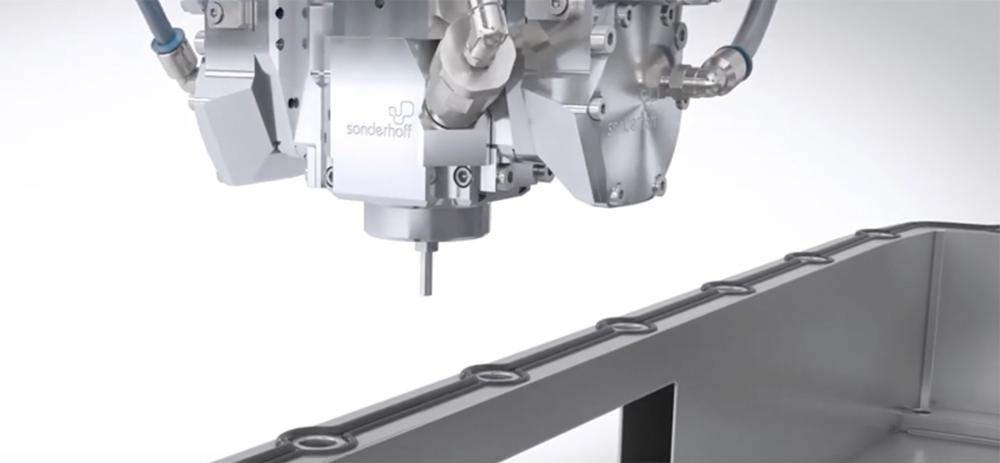

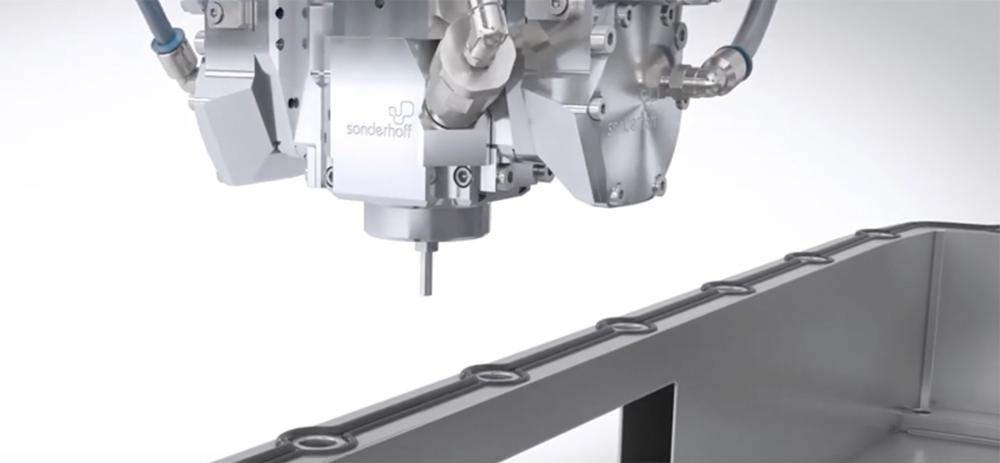

Fashioned-In-Place-Foam Gasket (FIPFG) Know-how — One significantly efficient providing in Henkel’s gasketing portfolio is their Sonderhoff formed-in-place foam gasket know-how. Already permitted to be used by one of many world’s largest EV producers, this resealable high-performance gasketing answer helps excessive manufacturing throughput, accommodates ongoing upkeep wants and meets extraordinarily demanding sealing necessities.

Sonderhoff FIPFG know-how supplies environment friendly, process-stable utility with brief tack-free and meeting instances for fast processing. In service, the froth gasket’s resetting skill and a number of compression/decompression capabilities permit the battery pack to be simply opened for upkeep and easily reclosed afterward. With excellent sealing IP lessons as much as IP 68 or NEMA 4 to six and NEMA 12, Henkel’s Sonderhoff gasketing options guarantee dependable safety from temperature extremes in addition to moisture, mud, and different contaminants.

Engineering Know-How Issues

Leveraging their in depth materials science experience, refined over a protracted and various testing and implementation historical past, Henkel engineers regularly innovate, file outcomes, and develop on earlier successes. With a formidable line of EV battery sealing, battery safety and battery security options, Henkel is supporting the newest EV design developments and staying on the forefront of the automotive trade’s shift to e-mobility.

Materials Information Playing cards — Not content material with merely responding to manufacturer-specified materials and efficiency specs, Henkel goes above and past to collaborate and advise on particular materials properties or in-service efficiency targets. To assist streamline prospects’ design and engineering efforts, Henkel goes past expectations by offering materials information playing cards for CAE simulations.

Flange Design Tips and Options Plus Expansive Community Help — An ever-growing crew of battery growth and supplies specialists at Henkel continually innovate to create new merchandise and formulations. Additionally they reply shortly to time-sensitive in-production requests with flange design pointers in addition to options from a broad, present portfolio. Additional strengthening this functionality, the worldwide Henkel footprint fortifies its groups with an expansive community of key amenities, educational experience and firmly established uncooked materials suppliers to capably tackle nearly each EV battery problem.

Partnership Issues

With its international attain, Henkel provides available native, regional, and international experience extending far past easy product choice and supply. Recognizing that electrification requires its personal set of design and engineering necessities distinct from inner combustion engine automobiles, Henkel has assembled its personal crew of e-mobility specialists to assist battery producers guarantee their design and execution is the very best it may be, proper from the beginning. Collaborating early within the battery design course of can save time, expense, and complications later – and maintain the producer’s repute intact. Via cost-saving simulations, the crew can shortly check quite a lot of supplies, movement properties, temperature ranges, bead thicknesses, and extra to establish optimum supplies for particular battery field perimeter seal functions.

New Battery Engineering Heart — Henkel takes its e-mobility partnership assist function severely by investing within the launch of recent Battery Engineering Facilities in key areas world wide. The Battery Engineering Facilities reassure and encourage EV producers, permitting them to see Henkel’s merchandise examined on their very personal batteries. By partnering with Henkel’s extremely succesful, obtainable employees across the globe, prospects can strategy their launch understanding they’ve a completely vetted answer on the prepared.

Profiles in efficiency

LOCTITE ESB 5100 Elastomer Sealant

- Authorised by a significant OEM to satisfy serviceability necessities for its EV battery pack lid seal

- Affords rapid dealing with after automated warm-applied allotting, stays comfortable and is well detachable for battery serviceability

- Easy accessibility to the battery pack promotes battery second life- and recycling circularity

- Silicone-free, corrosion-resistant and self-healing formulation provides wonderful adhesion to plastics

and aluminum - Suited to high-volume manufacturing of greater than 100,000 battery packs yearly

LOCTITE® 5970™ Silicone Sealant

- Authorised by a significant OEM for battery pack lid sealing

- Confirmed, single-component RTV-cure silicone formulation with a broad adhesion spectrum

- Semi-permanent sealer withstands excessive joint motion

Modern Foam Sealant Know-how

- Extremely serviceable — permits a number of reopening/closing cycles of the battery pack lid for repairs or recycling

- Brief meeting and treatment instances

- Expandable by as much as 300 p.c and compressible by 30 to 60 p.c

We Make Future E-Mobility Occur

Although its present portfolio of confirmed and modern e-mobility sealing, and adhesive supplies are readily serving to main producers obtain their EV aspirations, Henkel is already concentrating on greater accomplishments. Analysis groups are setting new efficiency requirements by means of enhanced product temperature and vibration resistance, easy and quick serviceability, accountable sourcing, sustainable manufacturing, and heightened battery circularity. New supplies, new approaches and new formulations are below method to assist include producer prices, pace manufacturing, scale back or get rid of curing instances and temperatures, and get rid of toxicity and flammability of their make-up. On the subject of reaching additional on behalf of their EV companions, Henkel makes it occur.

[ad_2]

Supply hyperlink

Leave a Reply