Extra Vary from Nickel-Wealthy Electrical Car Batteries

[ad_1]

Join each day information updates from CleanTechnica on e-mail. Or comply with us on Google Information!

A brand new nickel-rich, single-crystal battery expertise is on observe for fast deployment

A seemingly easy shift in lithium-ion battery manufacturing may pay huge dividends, enhancing electrical autos’ (EV) capacity to retailer extra vitality per cost and to resist extra charging cycles, based on new analysis led by the Division of Vitality’s Pacific Northwest Nationwide Laboratory.

An EV’s mileage will depend on the deliverable vitality from every of the constituent cells of its battery pack. For lithium-ion cells—which dominate the EV battery market—each the cell-level vitality capability and the cell price are bottlenecked by the optimistic electrode, or cathode.

Now that bottleneck may be opening up, because of an progressive, cost-effective strategy for synthesizing single-crystal, high-energy, nickel-rich cathodes that was lately revealed in Vitality Storage Supplies.

The nickel-rich battery imaginative and prescient

Cathodes for typical EV batteries use a cocktail of steel oxides—lithium nickel manganese cobalt oxides (LiNi1/3Mn1/3Co1/3O2), abbreviated NMC. When extra nickel is included right into a cathode, it significantly will increase the battery’s capacity to retailer vitality, and thus, the vary of the EV. Consequently, nickel-rich NMC (corresponding to NMC811, the place the “8” denotes 80% nickel) is of nice curiosity and significance.

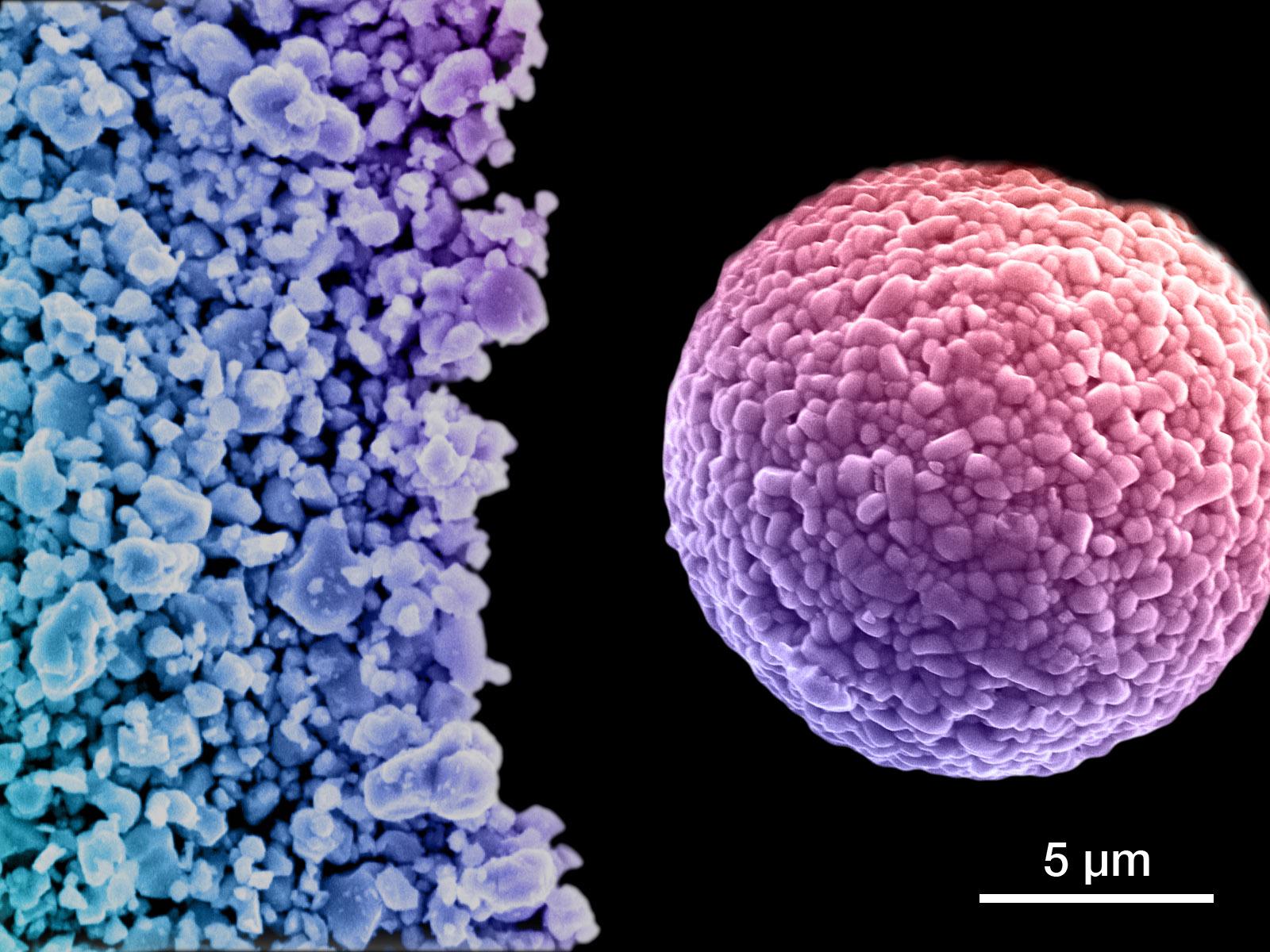

Nonetheless, high-nickel NMC cathodes fashioned utilizing the usual methodology are agglomerated into polycrystal buildings which are tough and lumpy. This meatball-like texture has its benefits for normal NMC. For NMC811 and past, although, the bulbous polycrystal fissures are vulnerable to splitting aside, inflicting materials failure. This renders batteries made utilizing these nickel-rich cathodes inclined to cracking; additionally they start to provide gases and decay quicker than cathodes with much less nickel.

Challenges of synthesizing single-crystal NMC811

One technique to repair this drawback: convert that lumpy, polycrystal NMC right into a easy, single-crystal kind by eliminating the problematic boundaries between the crystals—however this conversion is less complicated stated than achieved. In laboratories, single crystals are grown in environments corresponding to molten salts or hydrothermal reactions that produce easy crystal surfaces. Nonetheless, these environments usually are not sensible for real-world cathode manufacturing, the place lower-cost, solid-state strategies are most well-liked.

In these extra typical solid-state approaches, an NMC cathode is ready by mixing a steel hydroxide precursor with lithium salt, straight mixing and heating these hydroxides—and producing the agglomerated (lumpily clustered) polycrystal NMC. Utilizing a multiple-step heating course of leads to micron-sized crystals—however they’re nonetheless agglomerated, so the undesirable unwanted side effects persist.

PNNL’s answer

Led by PNNL battery specialists, and in collaboration with Albemarle Company, the analysis group solved these points by introducing a pre-heating step that adjustments the construction and chemical properties of the transition steel hydroxide. When the pre-heated transition steel hydroxide reacts with lithium salt to kind the cathode, it creates a uniform single-crystal NMC construction that appears easy, even beneath magnification.

“The one-step heating technique of precursors appears easy, however there may be a number of fascinating atomic-level part transition concerned to make the one crystal segregation attainable,” stated Yujing Bi, first creator of the paper. “It’s also handy for trade to undertake.”

Of their research, the researchers are actually scaling up this single-crystal NMC811 to kilogram degree by utilizing lithium salt offered by Albemarle. The scaled single crystals have been examined in lifelike 2Ah lithium-ion pouch cells, utilizing a regular graphite anode to be sure that the battery’s efficiency was primarily dictated by the brand new cathode.

The primary prototype battery geared up with the scaled single crystals was steady, even after 1,000 cost and discharge cycles. When the researchers seemed on the microscopic construction of the crystals after 1,000 cycles, they discovered no defects and a wonderfully aligned digital construction.

“This is a vital breakthrough that may enable the very best vitality density lithium batteries for use with out degradation,” commented Stan Whittingham, a Nobel Laureate and distinguished professor of chemistry at Binghamton College. “In addiiton, this breakthrough on long-lived batteries shall be essential to their use in autos that may be tethered to the grid to make it extra resilient and to help clear renewable vitality sources.”

The synthesis methodology for the single-crystal, nickel-rich cathode is each progressive and cost-efficient. It’s also straightforward to scale up, as it’s a drop-in strategy that enables cathode producers to make use of present manufacturing services to conveniently produce single-crystal NMC811—and even cathodes with greater than 80% nickel.

“This can be a basically new route for big scale manufacturing of single crystal cathode supplies,” stated Jie Xiao, the principal investigator of the undertaking and a Battelle Fellow at PNNL. “This work is simply a part of the cathode expertise we’re creating at PNNL. In collaboration with Albemarle, we’re addressing the scientific challenges in synthesis and scaleup of single crystals and lowering the manufacturing price ranging from uncooked supplies.”

Fast deployment of EV battery expertise

Within the analysis part, set to start in early 2024, PNNL, teaming up with trade and college companions, will work to comprehend commercial-scale synthesis and testing with a watch towards manufacturing.

To perform this so rapidly, they are going to use typical manufacturing tools and strategies which have been industrially tailored to incorporate PNNL’s scale-up strategy (in addition to just a few different improvements that additional cut back prices and waste technology).

“Throughout single-crystal synthesis on the kilograms degree, we now have recognized a model new world stuffed with science and engineering challenges and alternatives”, stated Xiao. “We’re excited to use this new data to speed up the commercial-scale manufacturing course of.”

“We aren’t competing with trade,” stated Xiao. “In truth, we’re partnering with trade leaders like Albemarle to proactively tackle the scientific challenges in order that trade can scale up the entire course of primarily based on the teachings and data that we realized alongside the best way.”

This work was supported by DOE’s Workplace of Vitality Effectivity and Renewable Vitality, Superior Supplies and Manufacturing Applied sciences Workplace, and Car Applied sciences Workplace.

Initially revealed on PNNL web site.

By Oliver Peckham, PNNL

Have a tip for CleanTechnica? Wish to promote? Wish to recommend a visitor for our CleanTech Discuss podcast? Contact us right here.

Our Newest EVObsession Video

https://www.youtube.com/watch?v=videoseries

I do not like paywalls. You do not like paywalls. Who likes paywalls? Right here at CleanTechnica, we applied a restricted paywall for some time, however it at all times felt flawed — and it was at all times powerful to resolve what we should always put behind there. In principle, your most unique and greatest content material goes behind a paywall. However then fewer folks learn it!! So, we have determined to fully nix paywalls right here at CleanTechnica. However…

Thanks!

CleanTechnica makes use of affiliate hyperlinks. See our coverage right here.

[ad_2]

Supply hyperlink

Leave a Reply